Hallo zusammen,

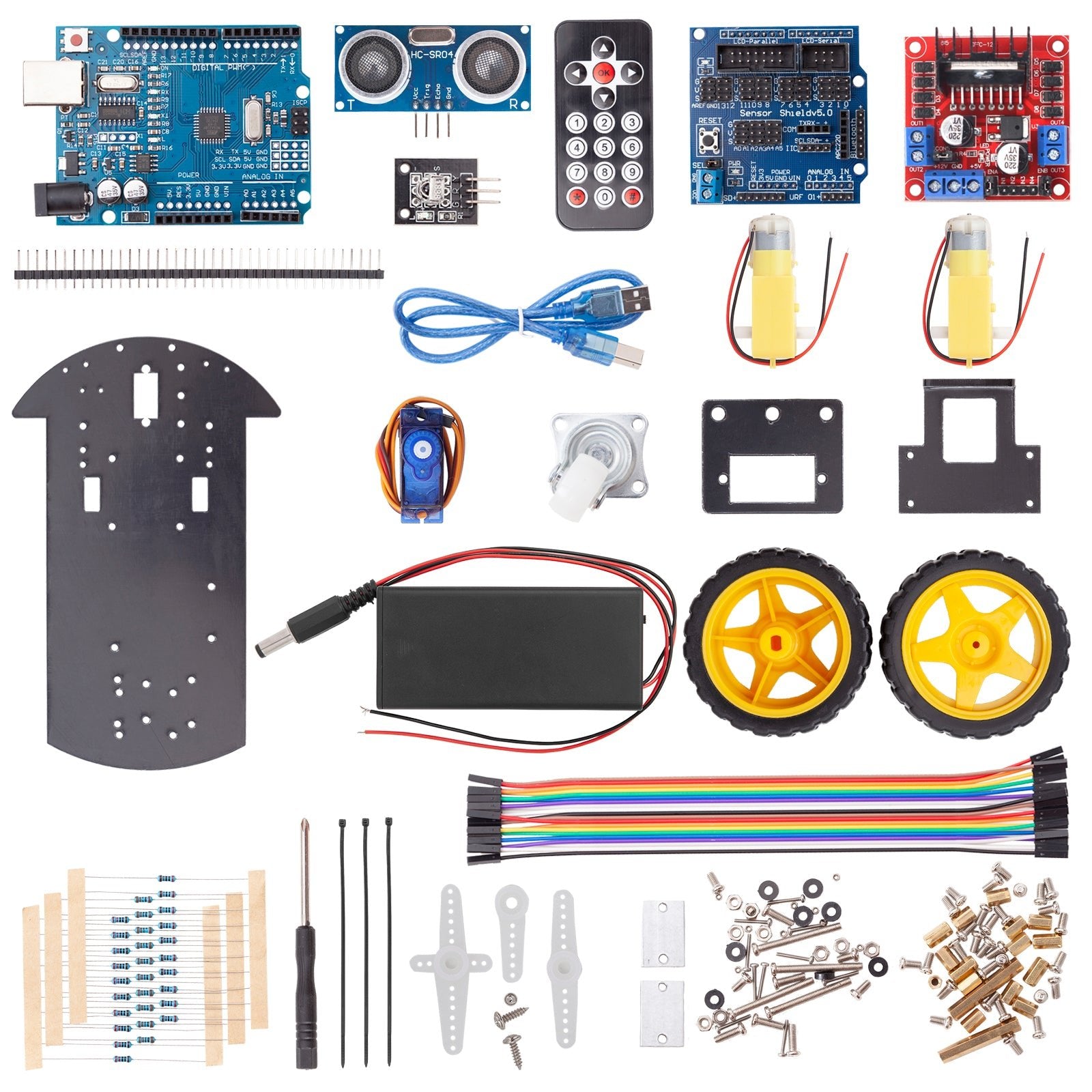

heute möchte ich Ihnen zeigen, wie man am schnellsten und einfachsten zu Gehäuse aus dem Lasercutter kommt. Einige erinnern sich vielleicht an unseren Blogbeitrag: Erste Schritte mit dem MP3 Modul. Damals musste noch eine alte Verpackung als Lautsprechergehäuse herhalten.

Heute, an Markus' freien Tag, möchte ich Ihm eine Freude bereiten und ein Gehäuse für das Projekt schneiden.

Ich habe vor einiger Zeit einen recht günstigen Lasercutter erworben und diesen für meine Ansprüche mit viel Zeitaufwand umgebaut (Sicherheitsschalter etc.)

Um nicht das Gehäuse komplett selbst zeichnen zu müssen haben wir uns eine Vorlage aus dem Internet gesucht. Für rechteckige Gehäuse ist www.makercase.com recht empfehlenswert, hier ein Screenshot:

Die Parameter am linken Bildschirmrand sind relativ selbstklärend, wir passen die Einstellungen an, um ein Gehäuse in der richtigen Größe zu bekommen:

Die besten Erfahrungen haben wir mit der Einstellung "Finger" gemacht. Da unser Material MDF 3mm dick ist stellen wir das unter dem Punkt "Material Thickness" ein. Nach dem klicken auf die Schaltfläche "Generate Laser Cutter Plans" öffnet sich ein weiteres Fenster, wir brauchen nur die Option "Vector Cutting" wo wir die Dicke unseres Laserpunkts einstellen können (bei unserem Gerät 0.3mm):

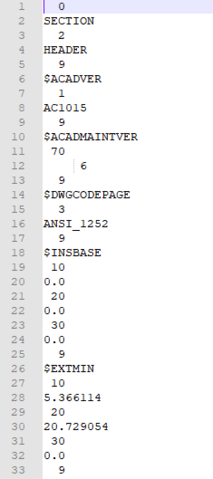

Nach dem Klick auf "Download" bekommen wir die Datei als SVG. Das SVG-Format stellt Informationen mit Vektordaten zur Verfügung. Diese besteht im Gegensatz zu Pixelbilden nicht aus einzelnen Punkten, sondern aus Linien bzw. Koordinaten. Sie können die Datei sogar mit einem Texteditor öffnen:

Viele CAM-Programme können die SVGs direkt laden. Sollte Ihr Gerät keine CAM-Software haben die SVGs unterstütz können Sie diese ganz einfach mit Inkscape in ein DXF umwandeln.

Dieses Format wurde von Autodesk entwickelt, um einen einfachen Dateiaustausch zu gewährleisten. Achten Sie beim konvertieren darauf, überall "mm" als Größenordnung anzugeben, damit die Maße stimmen.

Die CAM-Software die bei unserem Laser mitgeliefert wurde ist zwar nicht der Hit, liefert aber zuverlässig Ergebnisse und man kann einfache Dinge damit zeichnen und orientieren. Für Bastler also ausreichend, hier ein Screenshot mit importiertem DXF:

Die DXF im Editor sieht übrigens so aus:

Fehlen noch die Aussparungen für den Lautsprecher und die Knöpfe:

Die CAM-Software liefert sogar einen Simulator mit:

Nach dem Schneiden, das zusammengeklebte Gehäuse beim trocknen:

Die Löcher für die Knöpfe und den Lautsprecher passen ganz genau.

Wer jetzt Lust bekommen hat noch mehr zu schneiden sollte mal auf www.templatemaker.nl vorbeischauen.

Bis zum nächsten Beitrag :)

1 comment

Robert Stephan

Hallo Moritz,

das war ein schönes Projekt. Kannst du mir den Lasercutter weiterempfehlen oder würdest du heute einen anderen bevorzugen?

Was hast du verändert?

Lässt sich auch dickeres Material wie 3 mm MDF schneiden?

Danke und viele Grüße

Robert