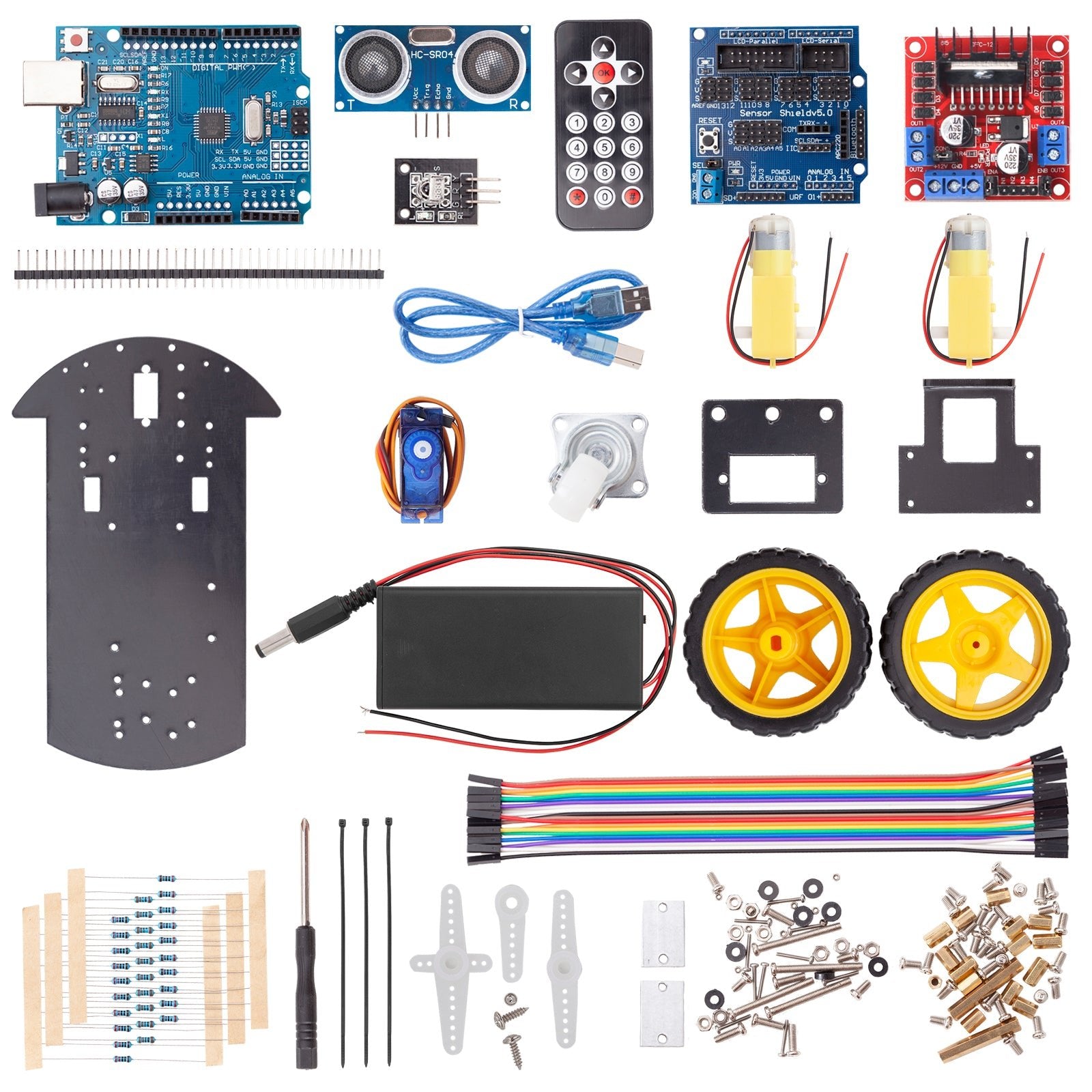

Heute wollen wir uns die Modellbauservos genauer betrachten. Genau genommen handelt es sich hier um einen Servoantrieb und nicht um einen Servomotor da die Steuerung bereits enthalten ist. Mit Servoantrieben die wir aus der Industrie kennen haben diese jedoch nur wenig zu tun. Wir haben den MG995, MG996R und SG90in unserem Lieferprogramm. Der SG90 ist der kleinste unserer Servos, dieser ist kleiner und leichter als die MG995/6R und findet hauptsächlich in Modellbauflugzeugen oder Modellbauschiffen Verwendung. Mit einem Gewicht von nur 9 Gramm und einem maximalen Drehmoment bis zu 1.6kg/cm ist dieser Servo vor allem da geeignet wo es auf ein geringes Gewicht ankommt, große Lasten können damit jedoch nicht bewegt werden.

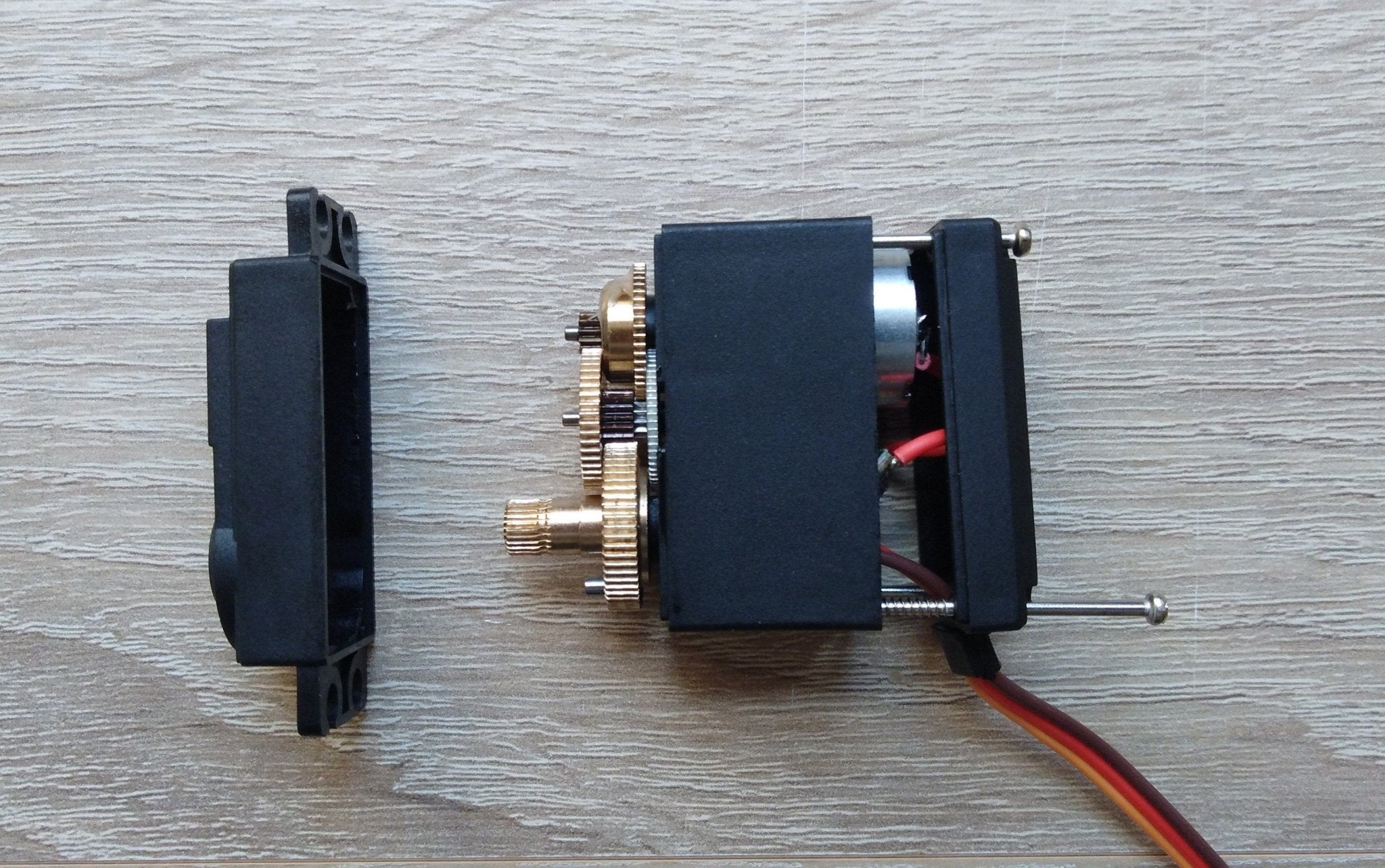

Deutlich größer und robuster mit einem maximalen Drehmoment von 9kg/cm ist der MG995. Dieser hat jedoch im Gegensatz zum MG996Rnur ein Plastikgetriebe, dafür ist die Stellgeschwindigkeit etwas höher. Das macht sich vor allem in der Lebensdauer unter Last bemerkbar. Das Drehmoment des MG996R wurde auch auf ca. 11kg/cm erhöht. Geöffneter MG996R:

Im Gegesatz zu Industriellen Servoantrieben werden Modellbau Servos mit Pulsweitenmodulation angesteuert:

Über die Breite der Pulse wird der Winkel, auf den der Servoarm gestellt werden soll, gesteuert. Gängig ist ein 50-Hz-Signal (20 ms Periodenlänge), welches zwischen 500 Mikrosekunden (linker Anschlag, 0 Grad) und 2500 Mikrosekunden (rechter Anschlag, 180 Grad) auf High-Pegel und den Rest der Periodenlänge auf Low-Pegel ist. Viele Servos haben in diesem Wertebereich jedoch nicht ihre volle Bewegungsfreiheit ausgenutzt und/oder können sich zwischen anderen Winkeln bewegen. Um den Bewegungsbereich zu erhöhen ist es möglichen den Servo zu "hacken". Dabei wird die mechanische Begrenzung im Getriebe entfernt (der kleine Stift am Zahnrad ganz rechts):

Zur Positionsregelung befindet sich im Servo ein Potentiometer, das mit der Ausgangswelle verbunden ist. Über dieses Potentiometer ermittelt die Servoelektronik den Ist-Winkel der Ausgangswelle (in der Mitte des Bildes zu erkennen).

Dieser wird mit dem Soll-Winkel verglichen, der aus dem PWM-Signal ermittelt wird. Bei einer Abweichung zwischen Ist- und Soll-Winkel regelt die Elektronik über den Motor und das Getriebe den Winkel der Ausgangswelle nach. Ein Nachteil von Modellbauservos ist, dass sich nicht abfragen lässt, ob der Servo überlastet ist. Das führt dazu, dass sich nicht feststellen lässt, ob der Servo überhaupt in der Lage ist, die gewünschte Position anzufahren. Manche Digitalen Servos lösen dieses Problem, aber das ist ein anderer Artikel

Bis zum nächsten mal :)

4 comments

Shakil

Like!! Really appreciate you sharing this blog post. Really thank you! Keep writing.

Willi

Wie hoch ist eigentlich die Zyklenfestigkeit der Servos bei 75% der max Last?

robby

DAS nicht der Drehmoment wird in Nm oder Ncm oder auch noch daNcm angegeben und nicht in kg/cm. Die angreifende Kraft wird wird mit der Länge des Hebelarms multipliziert und nicht durch diese dividiert. Das heißt, dass bei einem Drehmonent von 120Ncm in einer Entfernung von 10cm von der Drehachse am Hebelarm noch eine Kraft von 12N ausgeübt werden kann. Von einer Kraft ohne die Angabe der Hebelarmlänge zu sprechen ist schlicht Unsinn.

Maclaine

Ich finde es klasse das Ihr bei dem Servo den Drehmoment angebt und nicht wie beim Chinamann üblich die Haltekraft.

Dies ist die Kraft die man aufbringen muss um den Widerstand des Getriebes zu überwinden, sprich bis man den Servohebel drehen kann. Da stehen dann so Traumwerte wie 25 Kg.

Üblicherweise gibt man bei geeigneten Servos auch die Stellkraft bei zulässigen Voltzahlen an. 4,8 V ist ein Wert noch aus der Zeit von NC- Akkus.

Heute werden 6,0 Volt und 7,4 Volt angegeben ( Wert 2er Lipozellen).

Bei sogenannten Hochvoltservos , Kennzeichen HV, sogar bis 8,4 Volt.