Bevor Sie sich nun fragen, ob wir hier einen eigenen 3D-Drucker bauen werden, muss ich Sie enttäuschen. Diese Blogreihe wird sich nach und nach mit den Erfahrungen und teilweise Kniffen mit diversen Programmen beschäftigen.

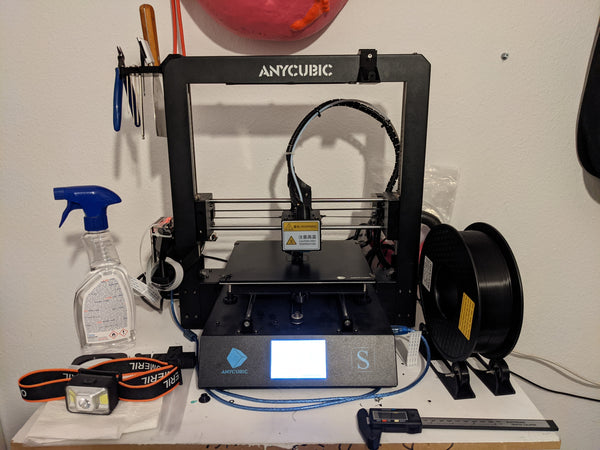

Ich selbst habe erst seit kurzem, Januar 2021, einen 3D-Drucker der Marke Anycubic. Es handelt sich dabei um ein Einstiegsmodel, reicht aber für die gängigsten Drucke vollkommen aus. Daher wird diese Blogserie in erster Linie eine Art Erfahrungsbericht, ein Tutorial im Bereich 3D-Druck und deren Programme, sowie die Lernkurve von mir wiedergeben. Seien Sie schon einmal gespannt darauf, was ich seit Januar 2021 alles gelernt, an meinem Drucker modifiziert und erweitert habe. Nach und nach sollen auch dann einige Programme vorgestellt werden, die ich für meinen Drucker verwendet habe. Ein Kernthema wird auch die Anbindung eines Raspberry Pi’s mit dem Drucker sein.

Diese Blogserie behandelt in erster Linie sogenannte FDM-Drucker. FDM steht für Fused Deposition Modeling, also das Modellieren im Schmelzschichtverfahren.

Die erste Berührung mit dem 3D-Drucker

Leveln, slicen, Gcode oder Filament sind nur einige (Fach-)Ausdrücke, die man im Zusammenhang mit einem 3D-Drucker liest. Zugegeben, fängt man mit dem Thema 3D-Druck(er) an, fühlt man sich wahrscheinlich innerhalb der ersten 5 Minuten wie ein blutiger Anfänger. Auch mir als technikaffiner Autor ging es da nicht anders. Mit meinem ersten Drucker, einen Anycubic i3 Mega S, fand ich einen günstigen, aber guten 3D-Drucker, der mich aber in die gleiche oben genannte Situation brachte.

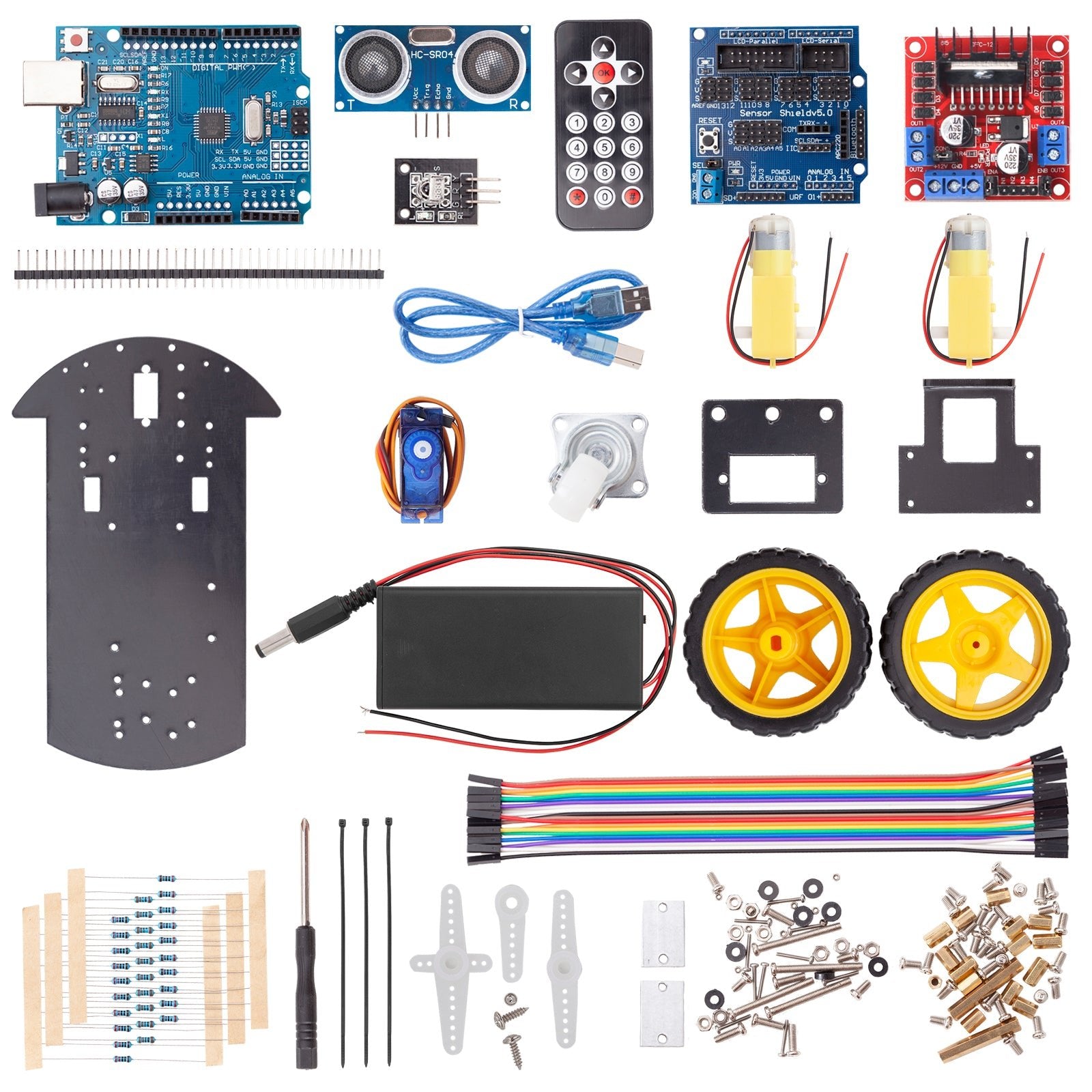

Abbildung 1: 3D-Drucker vom Autor mit einigen Zubehör

Je nach Modell und Hersteller ist der Zusammenbau einfach oder schwierig. Im Falle meines 3D-Druckers, war der Aufbau mit 8 Inbusschrauben und drei Kabel anstecken schnell erledigt. Es gibt jedoch andere Drucker, bei denen ist der Aufbau deutlich komplexer. Hier müssen die Motoren, der Rahmen und weitere Elektronik selbst montiert und angeschlossen werden. Dabei ist zu beachten, dass Sie mit 230V Netzspannung arbeiten und eigentlich eine entsprechende Ausbildung brauchen. Auf der anderen Seite gibt es Profigeräte, die vollkommen fertig bei Ihnen eintreffen. Haben Sie, je nach Modell, den Drucker dann zusammengebaut, kann es sein, dass noch weitere Schritte bis zum ersten Druck notwendig sind.

Den 3D-Drucker vorbereiten

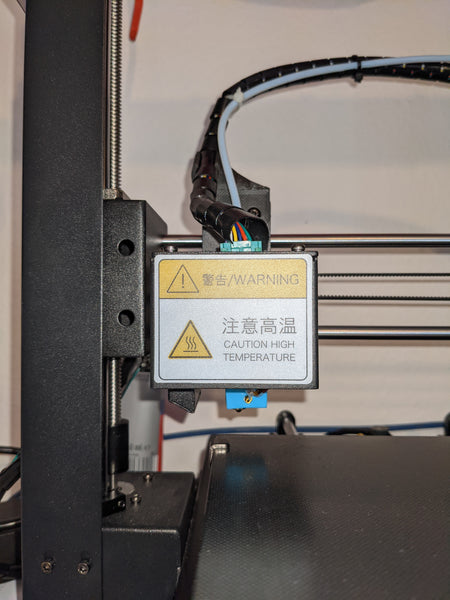

Hat man ein Problem beim Drucken, sind die ersten Kommentare in Foren, dass man das Heatbed ordentliche leveln soll. Mit Heatbed ist die Druckplatte vom Drucker gemeint, siehe Abbildung 2.

Dieser Vorgang muss bei den meisten günstigen Druckern direkt nach dem Aufbau vorgenommen werden. Es gibt aber 3D-Drucker im höheren Preissegment, die werden ab Werk komplett vorbereitet und müssen danach nicht mehr nachjustiert werden.

Abbildung 2: Heatbed vom Anycubic i3 Mega S

Das Heatbed hat seinen Namen, da es sich nicht um eine einfache bewegliche Oberfläche handelt, sondern um ein in der Oberflächentemperatur einstellbares Druckbett. Dieses kann auf Temperaturen bis ca. 70°C eingestellt werden, was von der Art des Filaments und weiteren Faktoren abhängt.

Das Leveln bezieht sich auf den Abstand zwischen Druckkopf und Heatbead. Genauer gesagt soll der Abstand zwischen Nozzle, die mit dem Hotend verschraubt ist, und Heatbead korrekt justiert werden. Was ist denn nun schon wieder ein Hotend und eine Nozzle? Das Hotend ist der Teil vom Drucker, der das Druckmaterial, das sogenannte Filament, auf die Temperatur bringt, in der es flüssig wird. Am Ende vom Hotend sitzt die Nozzle, die Spitze bzw. Düse, mit der das erwärmte Filament auf das Heatbed gebracht wird, siehe Abbildung 3.

Abbildung 3: Hotend mit Nozzle

Dies geschieht unter Druck, da der sogenannte Extruder das Filament in das Hotend schiebt. Mit Extruder ist eine Vorrichtung gemeint, die das Filament „greift“ und über Schläuche ins Hotend führt, siehe Abbildung 4.

Abbildung 4: Extruder am Rahmen vom Drucker

Ist also die Rede vom Leveln, so ist einfach gemeint, dass der Abstand zwischen Nozzle auf das Heatbed angepasst werden soll. Dazu positioniert man das Hotend an der Homeposition, also den Punkt {0,0,0} im Koordinatensystem des Druckers über den entsprechenden Menüeintrag. Vorher legt man ein dünnes Blatt Papier zwischen Nozzle und Heatbed und deaktiviert nach dem Erreichen der „Home“-Position die Motoren für alle Achsen. Je nach Hersteller wird empfohlen, bestimmte Punkte am Heatbed anzusteuern und über die Stellschrauben unter dem Heatbed den Abstand zu justieren. Man findet dafür im Internet viele Antworten, wann richtig gelevelt wurde. Mir hat es gereicht, wenn das Blatt zwischen Heatbed und Nozzle, leicht kratzt, wobei ich das Heatbed auf 60°C erhitzen lasse.

Allein in den letzten Absätzen haben Sie wahrscheinlich diverse Fachbegriffe gelesen und ggf. raucht der Kopf gerade ein bisschen. Ähnlich ist es auch mir ergangen. Seien Sie aber beruhigt, die Lernkurve ist zwar steil, aber viele Begriffe tauchen immer wieder auf.

Der erste Druck

Der oben genannte Ablauf dauerte bei mir um die 45 Minuten. Gerade weil das Leveln eine wichtige Rolle für alle Drucke spielt, sollte schon an dieser Stelle sehr gewissenhaft vorgegangen werden. Bevor die Frage aufkommt, das Leveln wurde von mir bisher sehr oft wiederholt, um das beste Ergebnis zu erzielen.

Kaum war das Leveln fertig, wollte ich natürlich sehen, ob alles korrekt justiert wurde. Viele Drucker liefern eine SD-Karte mit, auf der sich schon eine vorgefertigte gcode-Datei für den ersten Druck befindet. In meinem Falle beinhaltete diese erste Datei zwei kleine Eulen, die auf einem Baumstupf sitzen.

Diese wird über das Touchdisplay ausgewählt und der Druck kann starten, siehe Abbildung 5. Vorher muss man noch das Filament in den Extruder führen, da andernfalls nichts gedruckt werden kann.

Abbildung 5: Auswahl vom ersten Druck

Nach knapp 1,5 Stunden hatte ich dann auch endlich die fertigen Figuren in der Hand.

Zu beachten ist bei FDM-Druckern, dass sich Heatbed bzw. Hotend erhitzen und danach auch wieder abkühlen müssen. Daher dauert es recht lange, bis man das fertige Teil vom Heatbed nehmen kann, da die Haftung beim kalten Heatbed nicht mehr so stark ist.

Wie funktioniert der 3D-Drucker genau?

Das Prinzip hinter einem 3D-Drucker bzw. FPM-Drucker ist recht simpel. Über die drei Achsen X, Y und Z wird eine Position bzw. Strecke im Druckraum an- bzw. abgefahren. Je nach Position wird eine definierte Menge Filament aus der Nozzle gedrückt. Damit das so funktioniert, braucht der Drucker mehrere Dinge:

- Genaue Angabe über den Ablauf, was er tun soll.

- Die genaue Position des Werkzeugpunktes, der Nozzle, im Koordinatensystem vom Drucker.

- Während der Fahrt der Nozzle die genaue Angabe der Position im Raum.

Für den Verfahrweg oder die Position an den die Nozzle fahren soll, wird sogenannter gcode benötigt. Diesen können Sie sich vorstellen wie eine Art Programm. Schaut man sich diesen gcode einmal näher an, wird man Ähnlichkeiten zu einer CNC-Steuerungen, wie sie z.B. bei industriellen CNC-Dreh und -Fräsmaschinen, feststellen. Der gcode gibt Zeile für Zeile genau an, was der 3D-Drucker zu tun hat. Sei es den Lüfter der Nozzle einzuschalten, den Extruder Filament nachschieben lassen, oder eine bestimmte Strecke zu fahren. Diese Befehle werden von der Firmware des Controllers erkannt, meistens eine Marlin-Firmware, welche diese Befehle dann entsprechend umsetzt. Eine Übersicht aller gcodes, können Sie auf der Marlin-Homepage einsehen.

Damit ist schon einmal der erste Punkt der Liste geklärt, wobei noch nicht näher erläutert wurde, wie Sie an den gcode kommen. Dazu erfahren Sie im nächsten Beitrag mehr. Bleibt noch die Frage offen, wie der Drucker nun „weiß“ wo sich der Druckkopf im Raum befindet.

Dies geschieht in zwei Stufen. Wenn Sie einen Druck starten, fährt der Drucker zunächst die Urspungskoordinate 0,0,0 an. Sprich alle drei Koordinatenachsen fahren den sogenannten Nullpunkt an. Dieser ist meist durch ein oder mehrere Endschalter gesichert, die das Heatbed oder das Hotend auslösen, sobald Sie den Nullpunkt erreicht haben, siehe Abbildung 6.

Abbildung 6: Endschalter für die Y-Achse

Damit hat der Controller vom Drucker schon mal eine Referenz. Im zweiten Schritt kommen die verbauten Stepper Motoren zum Einsatz, siehe Abbildung 7.

Abbildung 7: Stepper Motor der Z-Achse (unten) und X-Achse (oben)

Diese Synchronmotoren können schrittweise gesteuert werden, wobei es keine Positionsrückmeldung gibt. Einen Encoder bzw. Drehgeber gibt es nicht, heißt also, der Controller vom Drucker geht davon aus, dass die richtige Position angefahren wurde. Das schreckt jetzt vielleicht im ersten Moment ab, aber die Stepper Motoren von 3D Druckern sind sehr genau. Damit -der Motor die korrekte Position bekommt, werden sogenannte Schrittmotor-Treiber-Module verwendet. Dieser steuert den Stepper Motor genau an.

In den meisten Fällen besitzt ein 3D-Drucker 5 Stepper Motoren:

- Einen für die X-Achse

- Einen für die Y-Achse

- Zwei für die Z-Achse

- Einen für den Extruder

Die Frage, die sich ggf. nun stellt, warum die Z-Achse den zwei Stepper Motoren braucht, wird beantwortet, wenn man sich ansieht, wie die X-Achse beim Drucker verbaut ist, siehe Abbildung 8.

Abbildung 8: Position der X-Achse

Die X-Achse hat zwei Schienen, auf der das Hotend über Fest- bzw. Loslager montiert ist. Da es über die gesamte Fläche vom Heatbed geht, müssen beide Seiten entsprechend korrekt positioniert werden, damit das Hotend nicht schief hängt. Bei Anycubic i3 Mega S ist das über zwei Gewindestanden, die mit den Stepper Motoren verschraubt sind, siehe Abbildung 7, gelöst. Somit ist denke ich auch klar, warum für die Z-Achse zwei Stepper Motoren nötig sind. Im höheren Preissegment gibt es andere Lösungen, aber die meisten Einstiegsmodelle nutzen das hier vorgestellte Verfahren.

Lohnt sich denn ein 3D-Drucker überhaupt für mich?

Die wichtigste Frage, die sich wahrscheinlich jeder stellen wird, ist, ob es sich überhaupt lohnt einen 3D-Drucker zu kaufen. Auch ich habe lange darüber nachgedacht und hatte mir viele Gedanken gemacht. Doch gerade als sogenannter Maker und für meine Kinder ist die Entscheidung für den Kauf eines 3D-Druckers ausgefallen.

Wohl gemerkt, dieser Beitrag zeigt erst einmal nur den Anfang in die Welt vom 3D-Druck und könnte Sie nun abgeschreckt haben. Hat man sich in das Thema aber erst einmal eingearbeitet und scheut nicht die steile Lernkurve, dann macht 3D-Druck Spaß und man beginnt selbst kleinere Dinge zu konstruieren. Die Frage ist also nicht, ob Sie als zukünftiger Maker überhaupt einen 3D-Drucker brauchen, sondern warum Sie noch keinen haben. Viele unserer Autoren haben selbst einen bei sich daheim und konstruieren für ihre spannenden Beiträge Gehäuse oder Teile für Ihre Blogbeiträge.

Aussicht auf den nächsten Beitrag

Aktuell haben Sie gelernt, wie ein 3D-Drucker grob funktioniert und worauf es beim Leveln ankommt. Das ist aber erst einmal nur die Spitze des Eisberges. Sie wollen, wie auch ich, eigene Projekte umsetzen oder noch mehr aus dem Drucker rausholen?

Ich möchte Sie auf die Reise mit einem 3D-Drucker mitnehmen, Fachbegriffe erklären und den Einsatz von einem Raspberry Pi in Kombination mit OctoPrint vorstellen.

Damit Sie auch etwas drucken können, braucht es gcode, aber woher kommt dieser und wie kommen Sie an interessante Druckteile? Auch hier gehen wir näher darauf ein. Zunächst stelle ich Ihnen die sogenannte Slicer-Software Cura vor, die ich aktuell benutze. Natürlich zeige ich auch, wo Sie interessante Druckvorlagen herbekommen und wie daraus dann der gcode wird.

Abschließen möchte ich das Ganze mit einer kurzen und knappen Einführung in die Software Fusion 360, mit der Sie selbst eigene Objekte erstellen können. Auf die Fragen, warum ich welche Software nun verwende, gehe ich in den jeweiligen Teilen genau ein.

Freuen Sie sich also jetzt schon, bald ihre Projekte nicht nur Hardware- und Softwareseitig zu perfektionieren, sondern auch gleich nötige Teile selbst zu kreieren und so immer mehr ein professioneller Maker zu werden.

Dieses und weitere Projekte finden Sie auf GitHub unter https://github.com/M3taKn1ght/Blog-Repo.

4 comments

Jörn Weise

Hallo,

was der Spaß kostet und was man braucht hängt stark davon ab, was man mit dem Drucker machen will. Ich habe mir den Drucker geholt um kleinere Gehäuse zu drucken, meinen Kindern über thingiverse.com Spielereien zu zaubern und für meine Projekte Bauteile zu erzeugen. Da reichte mir für den Anfang ein Anycubic Mega S vollkommen aus. Damit sind sie bei rund 250 Euro für das Gerät samt Filament. Werkzeug kriegen Sie meist beim Kauf vom Drucker gleich mit. Wenn Sie natürlich den Drucker modifizieren, geht das auch wieder ins Geld und Sie müssen halt wissen was Sie wollen und umbauen. Aber die Grenze nach oben ist offen, je nach Modell und Modifikation. Eine Kaufberatung oder Empfehlung gebe ich hier nicht, da können Sie in einem entsprechenden Fachforum gerne die Frage stellen. Problem ist, jeder hat da so seine eigene Meinung und Sie werden schnell auf diese eine Frage eine riesen Diskussion entfachen. Einfach mal im Netz gucken was es so gibt und welches Preissegment ihnen so vorschwebt. Auch ebay ist da eine gute Anlaufstelle, wobei Sie hier teilweise nicht wissen ob Sie ein Defektsystem bekommen, den der Käufer (wissentlich) verschwiegen hat.

Wolfhard Jording

Ich habe mittlerweile einige 3D-Drucker. Der Anycubic i3 Mega S ist mein bester. Mein erster Drucker war ein Bausatz für unter 150 €. Da habe ich fast 6 Monate daran rumgebastelt und sehr viel dabei gelernt. Mit OctoPrint habe ich immer wieder mal Probleme. Da bin ich gespannt, was davon im Blog erscheint. Am Raspi betreibe ich eine Sony Gaming Kamera, die ich in einem Spieleshop für 0,49 € gekauft habe. Die wurde sofort erkannt.

René

Flott und verständlich geschrieben, macht Lust zum Lesen und zu einem Kauf eines 3D-Druckers. Die Frage, die sich mir halt stellt ist die, was brauche ich zum was will ich herstellen mit Möglichkeit nach oben.

Und, letztendlich, was kostet das alles, Gerätekauf und Betriebskosten? Aber, topp Artikel und gespannt ob ich Antworten in den weiteren Artikeln finden.

Ralf Kastmann

Ergänzend möchte ich auf die Web-App Tinker-CAD: https://www.tinkercad.com/ hinweisen, mit der man auf einfachste Weise jede Art von 3D-Modellen kreieren kann. Ich habe alle meine Gehäuse und sonstigen Bauteile für Arduino etc. damit erstellt.

Ich mache seit ca. 2 Jahren 3D-Druck und habe insgesamt 3 FDM-Drucker und 1 DLP-Drucker im Einsatz. Die Lernkurve steigt dann nochmal exponentiell an, wenn man den Extruder und das Hotbed auswechseln muss, weil diese Teile nunmal verschleissen. Aber das kommt sicherlich in eine der nächsten Blogs.

Allen viel Spass beim 3D-Druck, was quasi ein Hobby im Hobby ist.